A unique piece need not cost a fortune. If you have a special anniversary coming up and want to mark it, send us an enquiry.

|

Commissions Welcomed A unique piece need not cost a fortune. If you have a special anniversary coming up and want to mark it, send us an enquiry. |

|

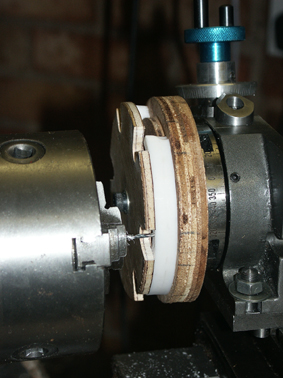

To minimise the waste (or maximise the potential quantity of cases) the centre was trepanned out from the 100mm dia Elforyn blank to leave a ring which could be cut into 6 pieces. The intention being to create two - 14mm wide cases with ebony cheeks and two - 21mm wide cases with a 1mm ebony stripe down the centre. | |

|

Once the major part of the centre had been removed, the 'ring' needed fine finishing to size. | |

|

Unfortunately due to lack of experience with this new material I gripped the ring too lightly - not wishing

to crush it - and on what would have been the final pass it came out of the chuck and shattered! This meant a serious re-think about how to get the maximum number of case blanks out of what was left. By careful trimming I decided that it was possible to get 3 pieces of the original design size out and one shorter piece. from this I could make one 21mm blank and two 14mm wide. |

|

|

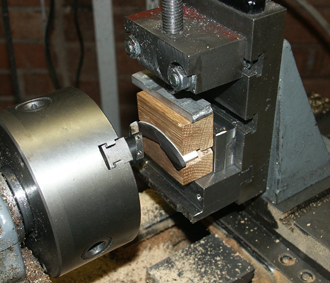

The original idea was to drill 2mm holes (to take the Stainless Steel strap anchors) around the ring at

7° and 57° intervals, cutting the blanks between the 7° spacings at 60°s. To achieve this the ring needed mounting on a rotary table with suitable clamping. With the changes needed after the disaster, one of the 57° spacing had to be changed to 49° and others missed out altogether. |

|

|

The two larger parts of the ring drilled for the strap anchors. | |

|

This part could proceed pretty much as originally designed. | |

|

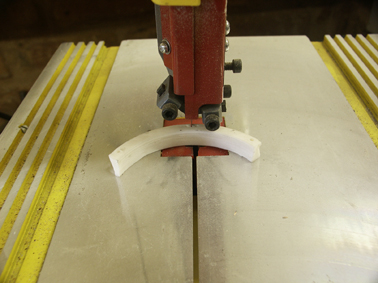

After sawing a 3mm thick Ebony sliver from the 15mm Sq the size of the Ivory could be marked out and the side cheeks trimmed roughly to size prior to being polished flat, assembled with the Ivory and the assembly trimmed. | |

|

|

|

|

With the side cheeks and/or centre stripe glued to the Ivory the outside could be faced to thickness. In the case

of the 21mm wide blank, the Ebony was trimmed back to 1.5mm before the second Ivory part was glued in position. To hold the case blank a special set of vice-jaws with matching radii had to be made. |

|

|

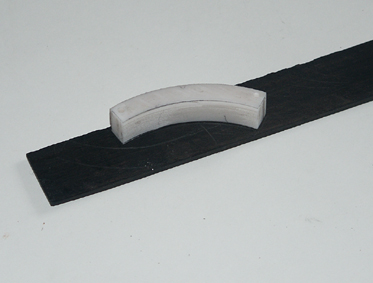

The shorter piece of Ivory was faced with Zebrano and due to the marked grain, left at 2mm thick to provide more of the detail. | |

|

The case backs will be 2mm thick and only need to be 15mm long so the smaller parts could be used. These were split on the bandsaw and will be machined to fit the cases once the movement apertures have been cut. |

Giant Watch

Giant Watch

|

History

History

|

Home

Home

|

Materials

Materials

|

|